SMART Compost Module

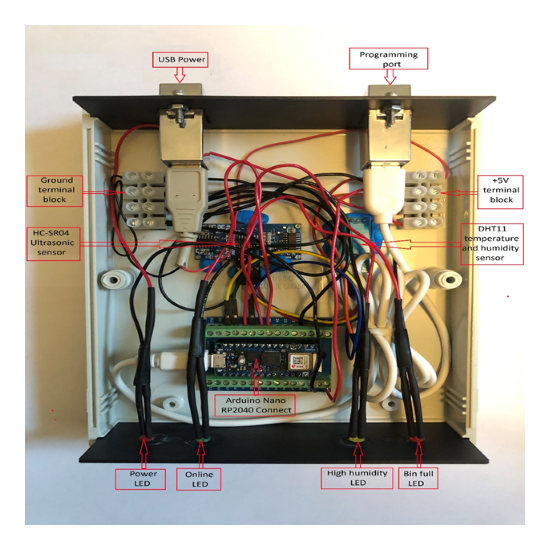

In light of the ongoing climate crisis, which is exacerbated in part by inefficient waste management systems, this project aims to tackle these challenges by designing a Smart Compost Module that enhances waste management processes. The primary focus of the design is on affordability, compactness, and ease of use, ensuring it can be widely adopted and effectively integrated into various environments. The module incorporates mechanisms to detect the bin's capacity, along with a system to monitor the waste’s humidity levels—an important factor, as humidity directly correlates to odor control. If any of these parameters fall outside optimal ranges, the system promptly alerts the user. All of this functionality is automated through the use of the Arduino Nano RP2040 Connect controller, which is equipped with an integrated IoT Wi-Fi framework. This enables seamless communication between the module and a dedicated mobile application, allowing users to remotely monitor and control the unit, thus providing a more efficient and user-friendly waste management solution.

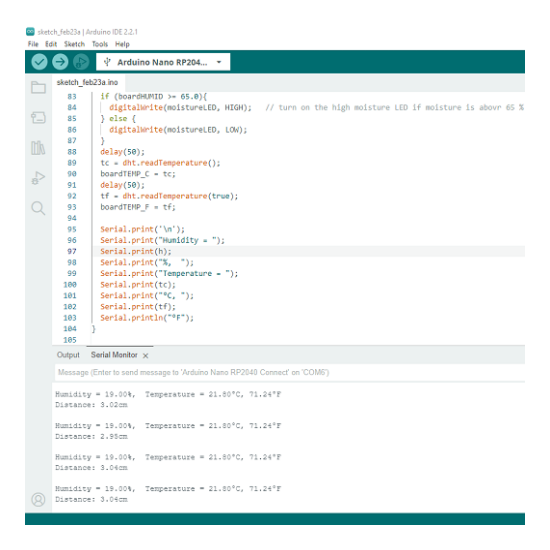

The design process for this project was divided into three distinct phases: simulation, implementation, and iteration. These phases were strategically chosen to streamline development, ensuring each stage contributed effectively to the overall success of the project. Furthermore, the design itself was subdivided into three key categories: mechanical, electrical, and software development, each of which played a critical role in the final product. During the simulation phase, the electrical aspects were modeled using NI Multisim, providing a robust platform for testing and analysis, while the mechanical design was initially conceptualized and sketched on paper. Once the simulation phase was complete, the focus shifted to software development, where coding and debugging took place within the Arduino IDE. This phase ran concurrently with the second stage of development, where the electrical and mechanical components were brought to life. For the electrical design, a standard breadboard configuration was employed to facilitate continuity and conduct rigorous stress tests, ensuring the reliability and functionality of the system before advancing to the final phase. Each phase of the process was carefully structured to maximize efficiency and precision, ultimately leading to a highly refined and functional prototype.

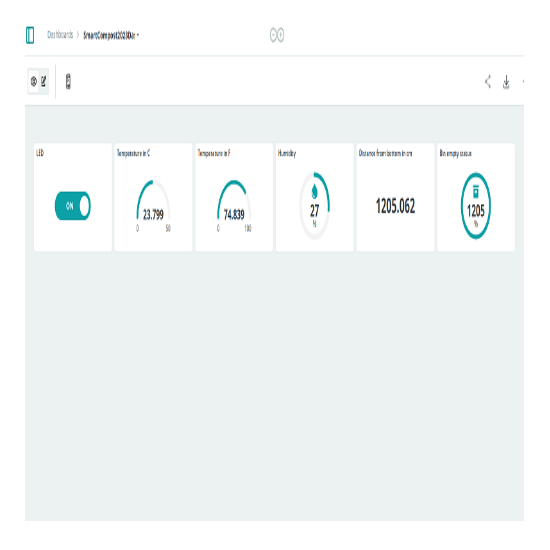

Iterative testing was integrated as a cornerstone of the design process, driven by the priority of delivering a high-fidelity final product. Each round of simulations and calculations provided critical figures of merit, which established the benchmarks and performance targets for the subsequent testing phases. The electrical design, in particular, was tasked with accurately detecting and emitting signals related to the data acquisition system, with the objective of maintaining a level of precision that surpassed a defined accuracy threshold. Following the electrical validation, attention was then directed to the mechanical design, ensuring that sizing requirements were carefully considered and seamlessly integrated. Once the electronic circuitry was finalized, the challenge of addressing energy dissipation emerged, which was resolved through strategic mechanical design. A series of prototypes were created and rigorously tested, leading to the development of an optimal mechanical configuration that effectively maximized heat dissipation, ensuring the electronics operated efficiently and reliably under load. On the software side, testing focused on coding each data acquisition component within the Arduino IDE, while also utilizing the Arduino mobile app for further integration. These tests were primarily centered on establishing stable Wi-Fi connectivity within the Arduino IoT framework, ensuring seamless communication between the hardware and mobile platform. Through this process of iterative refinement and comprehensive testing, every facet of the system was optimized, resulting in a robust, well-integrated solution ready for deployment.

During the parallel development process, the mechanical portion of the second phase focused on designing and 3D printing an affordable prototype chassis for the module using Blender. This initial prototype served as a proof of concept, allowing for rapid iteration and testing. As the project progresses into future stages, the next major step involves transferring the electronics onto a custom PCB circuit board, designed with precision using Altium Designer, to enable enhanced integration and efficiency. Additionally, a mobile application will be developed using React Native, providing seamless connectivity between the user and the module for remote control and monitoring. In terms of the physical design, the prototype chassis will be re-engineered using carbon fiber, a material chosen for its lightweight yet durable properties, ensuring improved performance and aesthetics in the final product. Several quality-of-life improvements will also be incorporated, refining both functionality and user experience. The culmination of these efforts will result in a high-fidelity, fully integrated product that closely aligns with the ideal final version, combining cutting-edge design, seamless user interaction, and superior material quality for an exceptional end result.